Background

Ultraviolet air and surface sterilization is becoming standard practice in the food industry, especially in greenhouse farming, where maintaining post-harvest freshness is just as critical as growing high-quality produce.

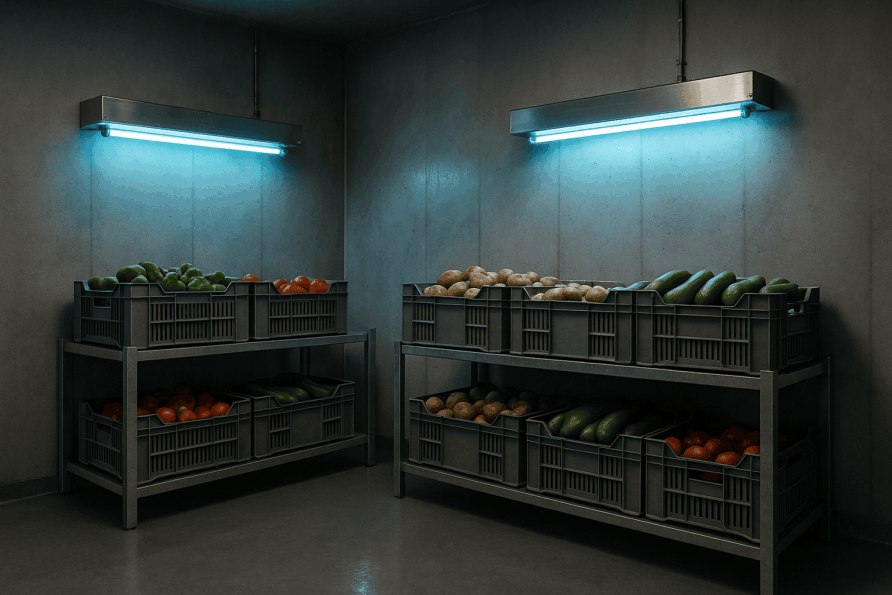

At the start of the year, a company specializing in year-round greenhouse vegetable production contacted us with a request to implement UV-based microbial control in a cold storage chamber designed for holding fresh vegetables.

Initial Conditions

- Storage Type: Refrigerated chamber

- Volume: 450 m³

- Floor area: 150 m²

- Ceiling height: 3 meters

- Temperature: +13 °C

The objective was to suppress microbial contamination in the air, reduce mold and fungal growth, and extend shelf life—without relying on chemical agents. Since the system would be installed above the product zone, all equipment had to meet strict food safety standards.

Chosen Solution: Open UV Fixtures with Shatterproof Protection

We recommended two UVL-Aero 100 open-type germicidal fixtures, equipped with shatter-resistant film coating on the lamps. This protective layer ensures safety even in emergency scenarios, while maintaining high levels of UV-C transmission. Our internal tests confirmed minimal light loss through the film, with no compromise in disinfection effectiveness.

Technical Specifications

- Type: Open UV fixture for air and surface disinfection

- Lamp: Ozone-free amalgam UVL 19310-144 VOSUV

- Lamp Power: 320 W

- UV Output: 105 W

- Wavelength: 254 nm

- Housing: Stainless steel AISI 304

- Lamp Life: up to 16,000 hours

- Effective Coverage: up to 300 m³

- Shatter protection: Laminated safety film

Delivery and Installation

After confirming the specifications, we signed the contract and issued a tailored invoice that included both equipment and logistics. The order was delivered within 10 working days.

Delivery Included:

- 2 × UVL-Aero 100 units with shatterproof protection

- UV lamps (model UVL 19310-144 VOSUV)

- Electronic power supplies (ballasts)

- Certified documentation, user manuals, packaging, and shipment

Implementation Results

The UV units were installed directly in the cold chamber and are now in full operation. Initial performance feedback confirms stable operation and high disinfection efficiency. The client is now considering an expansion to include four more UVL-Aero 100 units in other storage zones.

UVL: Sanitation Solutions for the Agricultural Sector

At UVL, we provide robust and efficient UV disinfection systems for air, water, and surfaces in agricultural and food-processing environments—such as greenhouses, dairies, bakeries, cheese factories, and vegetable storages.

Our systems are designed based on real-life operational conditions, production-specific requirements, and hygiene standards.

If your facility needs a reliable UV sterilization solution, the UVL team is ready to design, supply, and support the right system for your business.