One of the leading beverage manufacturers approached us with a clear objective: to implement a non-chemical water disinfection solution that meets strict hygiene standards. In the food and drink industry, any water used in production must be microbiologically safe — without altering the taste or composition of the final product.

Why UV Disinfection?

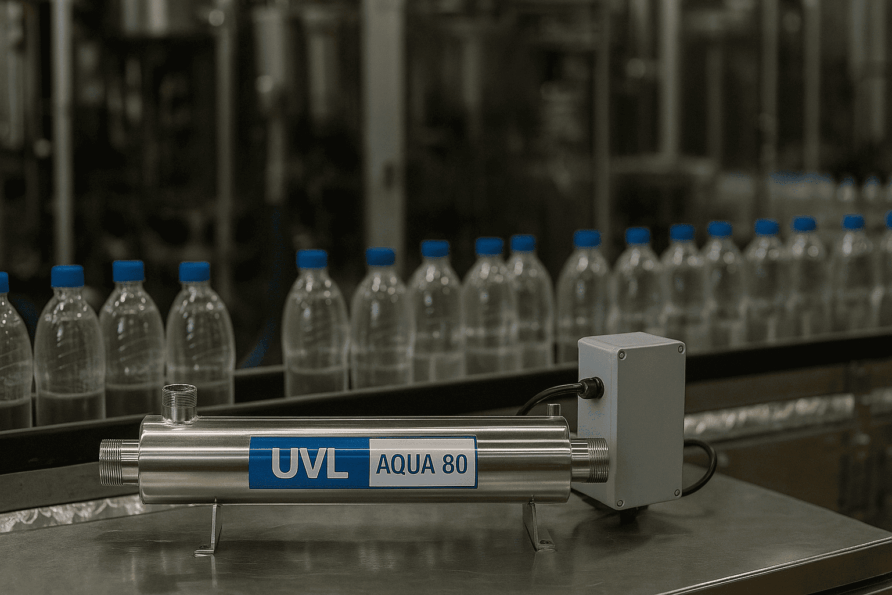

Ultraviolet (UV) technology has become increasingly popular in food processing. It offers highly effective sterilization without introducing chemicals, leaving no residuals, and preserving the natural quality of water. For this project, we proposed the UVL Aqua 80, a compact, flow-through sterilizer engineered for both drinking and process water treatment.

Equipment Overview

- Type: Inline UV disinfection unit

- Capacity: Up to 5 m³/h at 25 mJ/cm²

- UV source: UVL 80 HO, ozone-free germicidal lamp

- UV output: 17.5 W

- Housing: Corrosion-resistant stainless steel

- Lamp life: Up to 12,000 hours

- Package includes: Reactor body, quartz sleeve, electronic ballast (EPRA), sealing kit, and power cable

All UVL systems are equipped with proprietary high-output UV lamps that deliver consistent dosage and extended operating life. Optional features such as an integrated hour meter and sealed control unit are available for high-humidity environments.

Selection and Delivery

Initially, the client requested a system with a throughput of 7–9 m³/h. After consultation with their technical team, the UVL Aqua 80 was chosen as the most suitable model based on performance and installation compatibility.

The proposal included both the equipment and secure packaging for freight shipping. Delivery was handled through a logistics provider experienced in transporting sensitive UV equipment.

As an added service, the client also received a replacement UV lamp HNS 55W (55 Watt) for an existing unit — selected quickly based on a photo of the socket and lamp length.

Outcome

Integrating the UV disinfection system into the facility's water treatment line allowed the client to:

- Meet hygiene compliance standards without chemicals

- Eliminate the need for chlorination or oxidizing agents

- Reduce operational costs

- Achieve consistent microbial inactivation in continuous flow

Thanks to its reliability and minimal maintenance requirements, UV disinfection is increasingly favored in the beverage production sector.

UVL: Precision and Reliability in UV Sterilization

UVL offers a full portfolio of ultraviolet water and air disinfection systems, supporting clients from equipment selection to after-sales service. With deep experience in the beverage industry, we deliver proven, efficient solutions for water treatment and bottling operations — fast, accurate, and dependable.