Project Scope

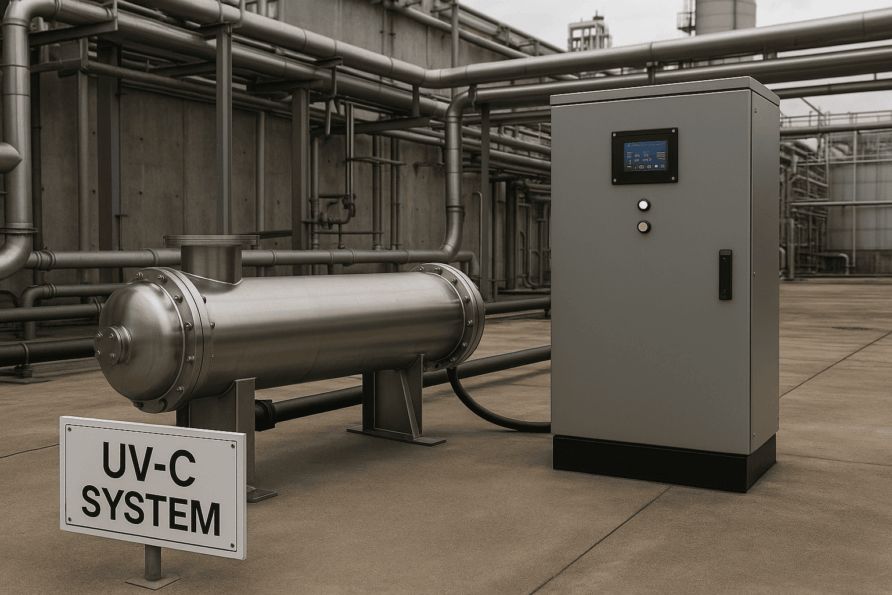

UVL successfully delivered a UV disinfection system model UVL-AQUA 30-700 for a major industrial complex operating in the chemical sector. The objective was to ensure safe, reagent-free treatment of stormwater runoff before discharge into natural waterways — meeting strict ecological and microbiological standards.

This project was part of a broader initiative involving the construction of a stormwater treatment station and water conditioning units for an environmentally responsible industrial infrastructure.

Initial System Parameters

- Treated medium: pre-filtered stormwater

- Flow capacity: 150–750 m³/h per unit, up to 1500 m³/h in dual-block configuration

- Water temperature range: +1 to +30 °C

- Operating pressure: up to 1.6 MPa

- Suspended solids tolerance: up to 5 mg/L

- Microbial purity target: ≤1000 CFU/L

Selected Solution: UVL-AQUA 30-700

After a thorough evaluation of the flow rate and site-specific conditions, we proposed the UVL-AQUA 30-700, an industrial-grade ultraviolet sterilization system designed to deliver consistent performance even with the presence of hydrocarbons and high turbidity.

Technical Specifications

- Lamp type: Ozone-free amalgam UV lamps (30 pcs)

- Lamp power range: 212–615 W each

- Total UV output: up to 6450 W

- Irradiance intensity: 1300 mW/cm²

- Lamp lifespan: up to 14,000 hours

- Housing material: Stainless steel AISI 304

- Operating pressure: up to 1.6 MPa

Each unit is equipped with an intelligent control panel featuring:

- Integrated UV sensors

- Remote monitoring capabilities

- Automated lamp usage tracking

- Real-time intensity control, ensuring consistent microbial inactivation even under fluctuating flow conditions

Delivery and Manufacturing Details

The standard package includes:

- UV disinfection chamber and smart control cabinet

- Full set of germicidal UV lamps

- Quartz sleeves

- Spare parts and a chemical cleaning device

- All technical documentation and user manuals

Production time: 90–110 business days

We also provided presentation materials, technical drawings, and commissioning documentation for integration into the site’s broader engineering plan.

Future Expansion

The project roadmap includes the phased installation of three UVL-AQUA 30-700 modules (two active units + one standby). The first delivery was completed successfully, laying the groundwork for future stages of expansion within the industrial complex.

Conclusion

This project demonstrates the value of UV-based wastewater disinfection at industrial sites with high ecological responsibility.

The system ensures:

- Effective pathogen elimination

- Stable operation under high hydraulic loads

- Compliance with modern environmental and sanitary standards

Looking for a dependable UV disinfection system for your facility?

Get in touch with UVL specialists — we’ll design the solution, prepare documentation, and support you throughout implementation.