UVL is a manufacturer of ultraviolet disinfection systems for water, air, and surface sanitation. We engineer complete UV installations, lamps, and modular systems that help industrial clients maintain hygiene and automate critical operational processes.

Project Overview

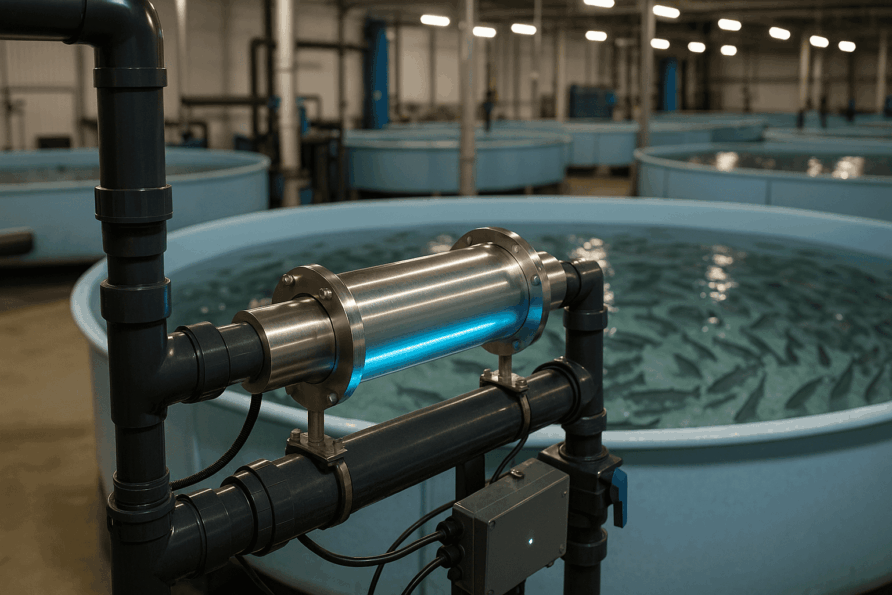

A large aquaculture facility using Recirculating Aquaculture Systems (RAS) approached us with a need for reliable water disinfection. In RAS, the same volume of water is continuously cycled through filtration and treatment units several times per day, making it essential to maintain a consistently high microbiological quality to prevent the spread of bacteria, viruses, and parasites.

The Challenge

Previously, the farm used only basic filtration. As production volumes increased, they faced new challenges:

- Deep microbial decontamination in a continuous flow

- Operation without chemical disinfectants

- Minimum flow rate: 400 m³/h

- Protection from external pathogens and internal contamination

- Integration with existing piping and components

- Demand for spare parts and backup lamps

- Waterproof, automated systems for harsh conditions

UV disinfection in aquaculture is often applied:

- Inside the recirculation loop to prevent internal microbial growth

- At water intake to block external contamination

- Post-ozonation, for ozone decomposition and final sterilization

The Solution: Flow-Through UV Systems

After a detailed evaluation, UVL engineers recommended installing two UVL-Aqua 800 flow-through disinfection systems, each capable of handling 170 m³/h, with upgrade potential to 400 m³/h by parallelization.

These UV reactors are corrosion-resistant, suitable for humid environments, and ideal for indoor installation.

UVL also offers submersible UV modules as an alternative. These can be directly placed in tanks or filter chambers and offer:

- Reduced cost (no stainless housing)

- Easier installation

- Flexible scalability by adding modules as needed

Equipment Details

Each UVL-Aqua 800 system included:

- AISI 304 stainless steel housing

- 2 × UVL 32800 UV lamps + 2 spare lamps

- Quartz sleeves for protection

- Waterproof cables and ceramic connectors

- Electronic ballasts (6.4 A) with integrated status indicators

- Support for horizontal or vertical mounting

Performance Output:

- Up to 55 m³/h at 40 mJ/cm²

- Up to 85 m³/h at 25 mJ/cm²

- Lamp power: 160 W

- Wavelength: 254 nm (UV-C)

- Lamp life: up to 16,000 hours

- Ozone-free lamps — safe for fish

The delivery also included a control cabinet (IP41), waterproof connections, and a sight glass.

Implementation and Delivery

Once approved and prepaid, the full order was assembled, securely packaged, and shipped via a logistics provider. All equipment was delivered intact and on time. The package included spare lamps and consumables, allowing seamless integration into existing infrastructure.

UVL offered a 12-month warranty, with a simple replacement process — no paperwork required, just a photo of the defect.

Installation was rapid and did not require downtime, thanks to compact design and detailed documentation.

Results and Benefits

The system now provides UV water disinfection at both the intake and within the recirculation loop. Key outcomes include:

- Reduced manual intervention and maintenance

- Elimination of chemical disinfectants

- Increased sanitary stability in fish tanks

- Easy future system expansion

UVL delivers tailored UV solutions for aquaculture. We offer both flow-through systems and submersible modules, customized for the specific conditions of your farm.