We design and manufacture professional UV equipment—lamps, control cabinets, and turnkey systems for disinfection of air, water, and surfaces. Below is a case study of a project where we engineered and delivered a non-standard set of UV irradiators for conveyor lines.

Project Background

A manufacturing facility producing sanitary and hygiene products—including pads, medical masks, and wipes—required a robust UV disinfection solution for its automated conveyor lines. The plant’s hygiene standards were extremely strict, especially in preparation for third-party audits.

Challenges

The client needed:

- Precise UV dosing for multiple conveyor lines.

- Integration into limited installation space.

- Comprehensive documentation meeting international audit requirements.

Previous options such as recirculators and ozonators failed to deliver stable UV intensity or sufficient certification support.

Proposed Solution

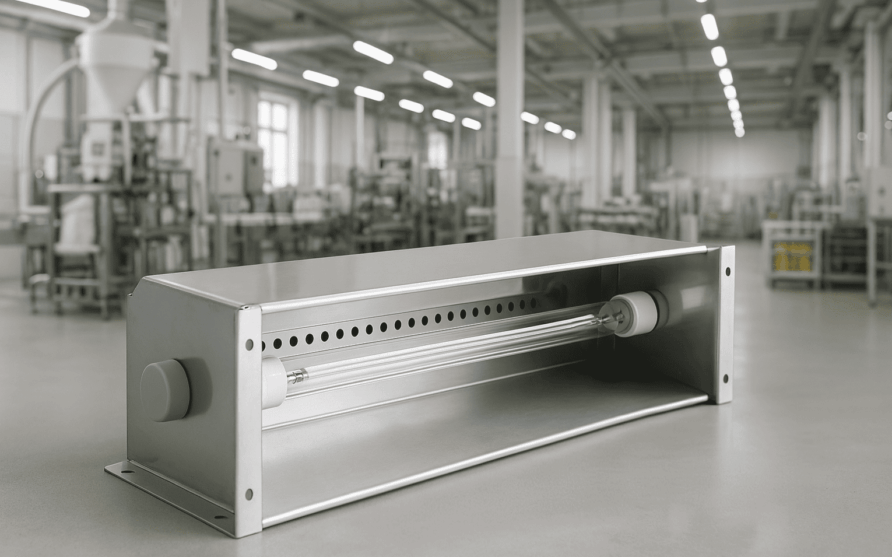

Following technical consultations, we proposed four UV conveyor irradiator models with tailored dimensions and lamp configurations:

- VOZUF 810 /200/ 410 mm – three-lamp model.

- VOZUF 150 mm – seven-lamp model.

Additionally, we supplied control cabinets with electronic ballasts (EPRAs) featuring:

- Remote UV lamp monitoring.

- Operating hour counters and status indicators.

- Integration options for the client’s IT system.

Each UV section used amalgam lamps rated up to 55 W, delivering a total UV power of up to 385 W depending on configuration. Calculations considered conveyor speed and lamp height—for instance, at 100 mm height and 5 m/s speed, the UV dose reached 27.5 mJ/cm², meeting hygiene standards.

Implementation Process

We shipped the first control cabinet separately to align with the client’s schedule, while UV irradiators were delivered progressively as housings were completed. Communication with the chief engineer ensured continuous feedback and adjustments. Early-stage documentation, including advance invoices and electronic records, was prepared to meet audit requirements.

All components were manufactured, tested, and dispatched on time. The equipment is now fully integrated into the production process, delivering stable UV disinfection across all conveyor lines.

Benefits for the Client

- Stable, reliable ultraviolet sterilization for high-speed conveyor lines.

- Documentation and technical support tailored for audit compliance.

- Modular design adaptable to changing production needs.

- Safe operation for staff through recommended protective shielding materials.

Need stronger hygiene control and an efficient disinfection stage on the line?

We’ll engineer and supply a UV system matched to your footprint, throughput, and process requirements.