UVL designs and manufactures ultraviolet disinfection systems for air, water, and surface sterilization in industrial applications. We specialize in amalgam UV lamp technologies and custom UV modules for food processing facilities operating under strict hygiene standards.

Client Request

A food and beverage production facility approached us with a need to integrate an automated UV disinfection system for PET bottle caps directly on their bottling conveyor line. The key objectives were:

- Hands-free disinfection with no human contact

- Compact dimensions to fit into a restricted integration zone

- Moisture-resistant housing suitable for humid conditions

- Compliance with food industry hygiene protocols

The conveyor ran at 26 meters per minute, with a belt width of 100 mm and no personnel present in the treatment zone.

The Challenge

The client required a non-contact, fully automated solution that:

- Operated without chemicals

- Could be installed without altering the production line

- Provided shatterproof protection and mercury containment in case of lamp failure

- Delivered a consistent UV dose in a high-throughput setting

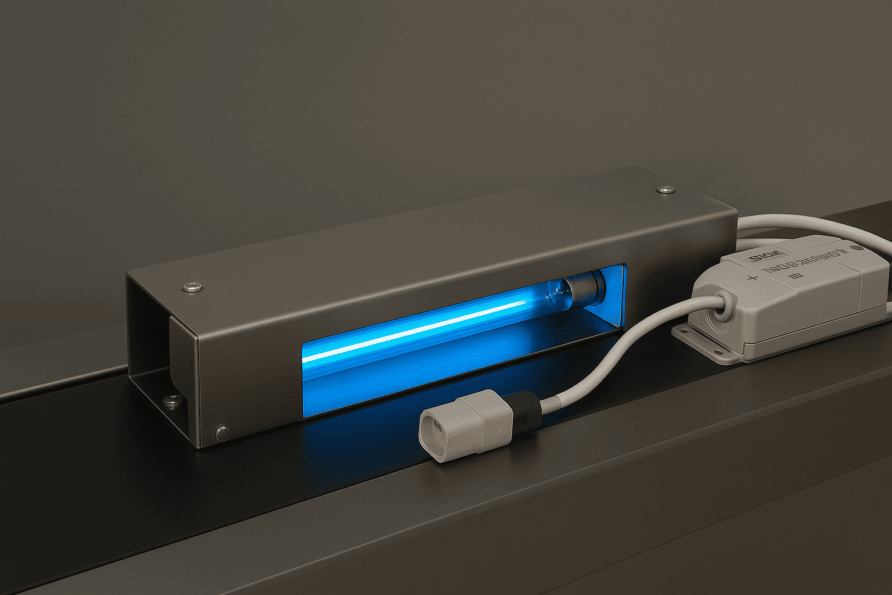

Our Solution: Standardized UVL Sterilizer Module

We proposed a pre-engineered unit: the VOZUF-410 mm UV irradiator, equipped with a high-efficiency UVL 1980 amalgam germicidal lamp. This lamp:

- Has a shatter-resistant coating to prevent contamination

- Contains chemically bound mercury, making it safe for food facilities

- Offers a 16,000-hour lifespan and is temperature-tolerant

As the product was in stock, the client was able to:

- Avoid costly redesigns and delays

- Receive fast shipment

- Install the unit with their own technical staff

- Eliminate the need to halt the production line

Equipment Specifications

- Irradiator Model: VOZUF-410 mm

- Housing: Stainless steel AISI 304

- UV Lamp: UVL 1980, amalgam, ozone-free

- Ballast: EPRA L-220-1x320-2212-150

- Connection: 4P SE ceramic connector with leads

- Installation Height: 5–20 cm above conveyor

- Startup Time: 1–2 minutes to full UV output

The system was delivered as a compact integration kit, including:

- UV irradiator with mounting hardware

- Germicidal lamp and power supply

- Installation and operation manuals

- Protective transport packaging

The power supply was designed for easy integration into existing cabinets with no need for new electrical infrastructure.

Implementation

Once the technical details were approved, we issued an invoice and prepared the shipment. Despite high warehouse activity, the order was delivered on time, complete with documentation and installation instructions.

Results

The UV disinfection module was installed and commissioned without stopping production. It now provides:

- Continuous packaging sterilization without operator input

- Reduced risk of microbial contamination

- Full compliance with hygiene regulations

- Reliable operation in a humid environment

UVL offers a full range of UV disinfection systems for food production — from ready-to-install modules to custom configurations. Whether you need amalgam lamps, stainless housings, or complete solutions, we deliver systems tailored to your production line.