Project Overview

A sauce packaging facility needed to secure the quality of process air used for bottle movement and filling. Because open containers contact the airstream, even minor contamination can lead to secondary product pollution. The plant asked for a solution that fit the existing ventilation layout with no duct reconstruction.

A parallel request covered three compact bactericidal UV sections sized 200×200×1300 mm, each serving localized areas at 1,200–1,300 m³/h.

Solution

We proposed a dual configuration:

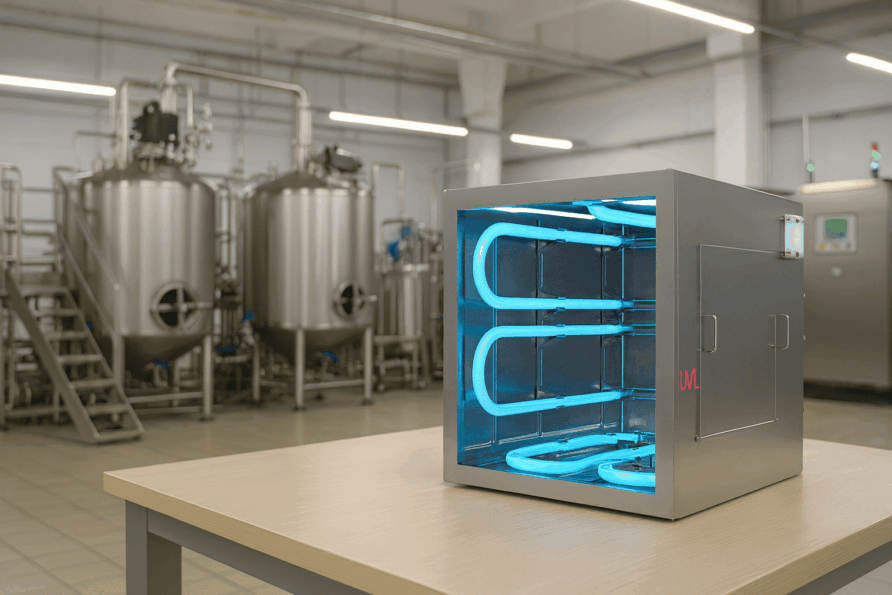

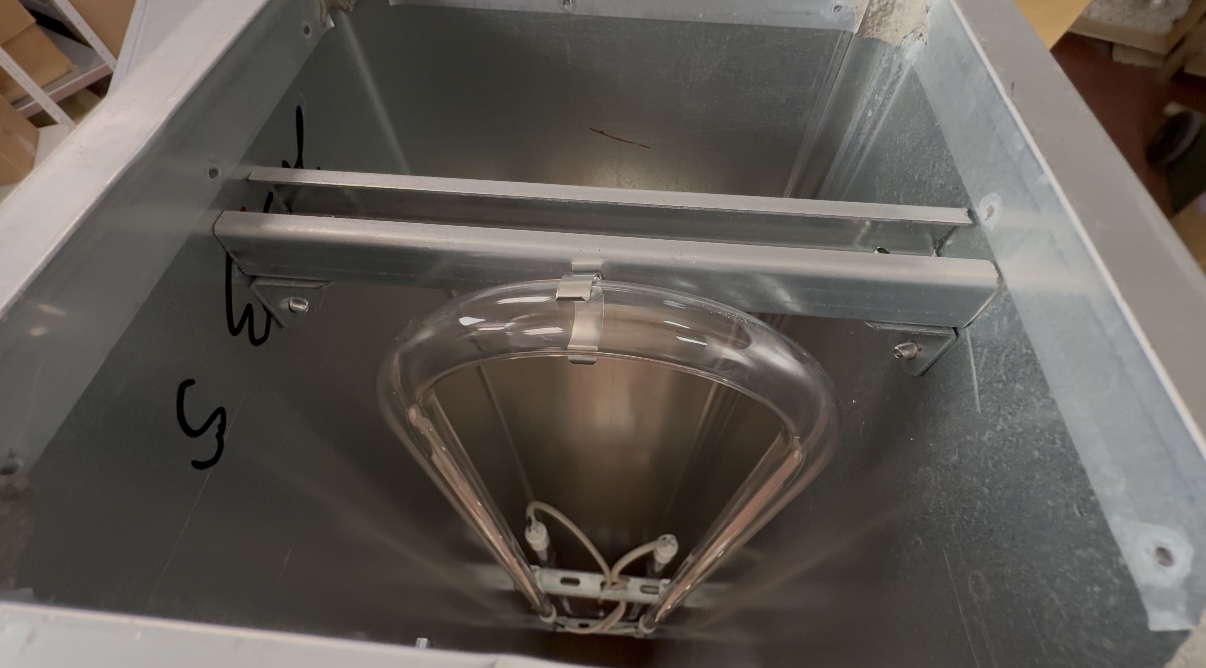

Three UVL-Aero 2 sections

- For 200×200 mm ducts, up to 1,300 m³/h each.

- Housing and flanges customized to client drawings.

One UVL-Aero 12 high-capacity section

- Disinfects up to 13,000 m³/h in the central ventilation channel.

- Equipped with 12 amalgam UV lamps for robust, uniform exposure.

The delivery set included six spare UV lamps UVL 19310-144 FLOW, a single-channel control cabinet for one electronic ballast, a 12-channel cabinet for multi-lamp control, and electronic ballasts L-220-1x320-2212-150, plus documentation confirming food-grade suitability.

Implementation

We coordinated closely with the plant’s chief mechanic: clarified drawings, service-hatch placement, and electrical tie-ins; then issued a full technical description for audits and internal compliance. Despite split payment terms, production began immediately. Installation and commissioning finished on schedule; the system is fully operational and meeting performance targets.

Why This Approach Works

- End-to-end coverage: A UV disinfection system in the main duct plus targeted sections for local points of risk.

- Seamless fit: Custom geometry preserves the existing air-handling architecture.

- Serviceability: Centralized cabinets with electronic ballasts simplify control and maintenance.

- Food-safe design: Ozone-free germicidal lamps at 254 nm provide effective air sterilization without chemical residues.