Our company develops and manufactures bactericidal UV lamps, components, and complete systems for the disinfection of air, water, and surfaces. From amalgam lamps and electronic ballasts to fully assembled units — we deliver solutions for both standard and custom-designed applications.

Project Overview

This project was carried out for a private medical clinic equipped with a Category “A” surgical unit. According to the facility's technical standards, air must pass through vertical recirculation columns before entering a laminar flow zone above the operating table — a sterile area critical to infection control in surgical environments.

Such ventilation systems generate a continuous stream of purified air, free from bacteria and viruses, which plays a key role in preventing healthcare-associated infections (HAIs).

Initial Challenge

Our task was to integrate UV air disinfection into an existing supply and exhaust ventilation system. The requirements included:

- Disinfection of up to 5000 m³/h per air column

- Adaptation to a rectangular duct section of 830×600 mm

- Use of a straight duct section approximately 1 meter long

- Operation in warm indoor air environments

- Availability of both a pre-assembled UV section and a DIY integration kit

Reliability of all components was crucial. The clinic had previously used UVL lamps and confirmed their consistent performance in critical healthcare environments.

Additionally, the system needed to deliver germicidal radiation at 254 nm, effectively destroying pathogens, including spore-forming bacteria, by disrupting their DNA and RNA.

Technical Solution

Two approaches were proposed:

- UVL Aero 6 UV Section — a duct-mounted unit with up to 5000 m³/h capacity, designed for 400×700 mm air ducts

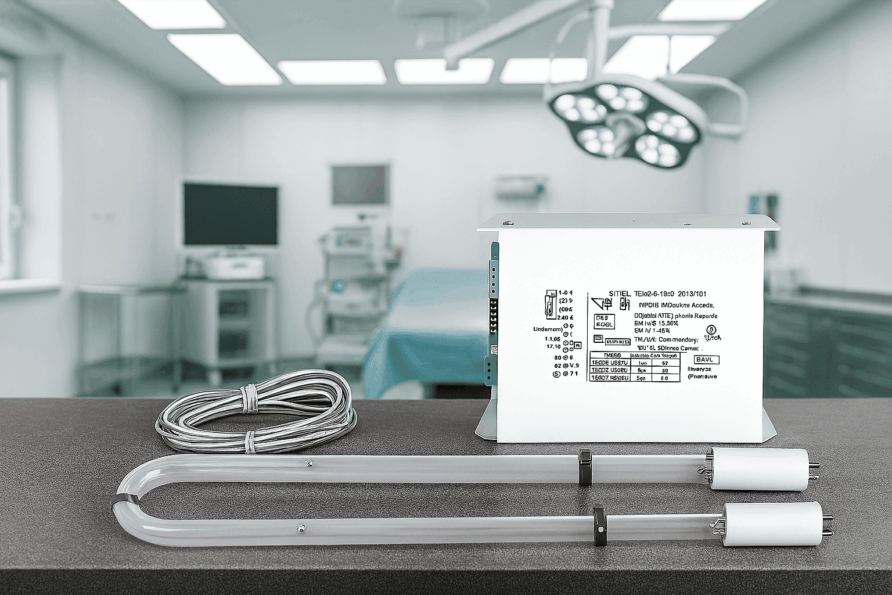

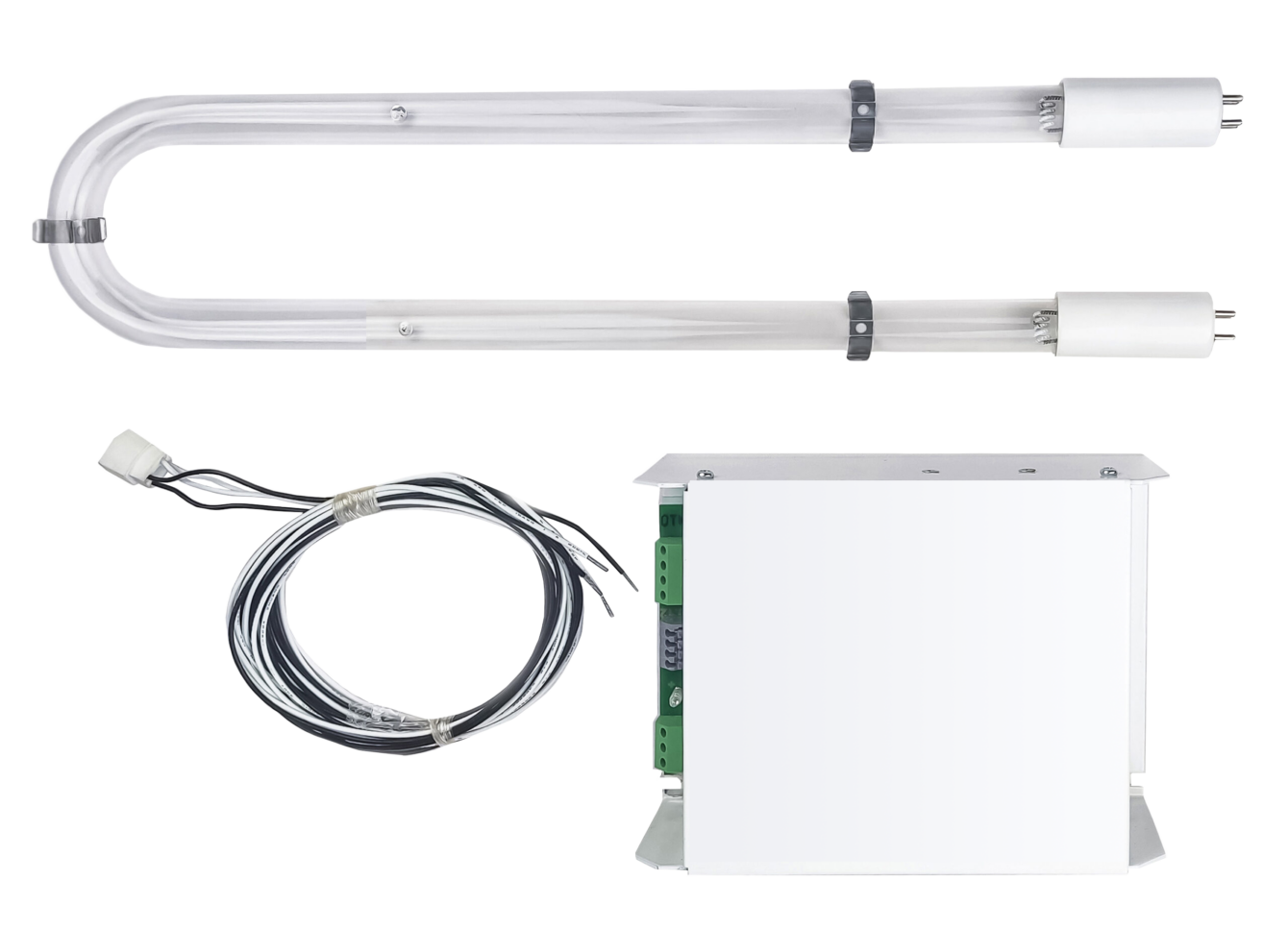

- Custom UV Kit — a set of components including amalgam UV lamps, power supplies, mounting clips, and connectors for flexible integration

After technical consultations with the clinic’s engineering team, the second option was selected. It enabled precise installation of the UV sources directly inside the column housings based on their layout and duct routing.

Equipment Supplied

To meet the project goals, we delivered:

- 54 UVL 19310-144 FLOW amalgam UV lamps — each rated for 16,000 hours of continuous operation

- 54 electronic ballasts (EBRA L-220-1x320) — matched to the lamp specifications

- 162 T5 metal clips — for secure and safe lamp mounting

- 108 four-pin ceramic connectors — pre-wired with 2000 mm cables for reliable electrical connections

This setup enables effective air disinfection inside HVAC systems, achieving up to 99% reduction of Staphylococcus aureus, making it ideal for use in sterile zones like surgical rooms and clean areas.

All components were manufactured by UVL and fully compatible with each other. Secure packaging protected all items during transit. If any lamp was damaged during delivery or failed within the first year, replacement was provided upon photo confirmation, no paperwork required.

Execution

A detailed quote and technical breakdown were sent to the client the same day. Both options — the preassembled UV section and the modular kit — were proposed based on the site’s specific conditions. Thanks to excellent communication and mutual efficiency, the specifications were finalized quickly, the contract signed, and the equipment delivered on schedule.

This project proves once again that even in complex environments with strict constraints, it’s possible to implement reliable UV air disinfection solutions that meet all technical and sanitary standards.

If you're planning to implement UV air disinfection in hospitals, labs, or critical medical zones — contact us. We’ll design a system that truly delivers.