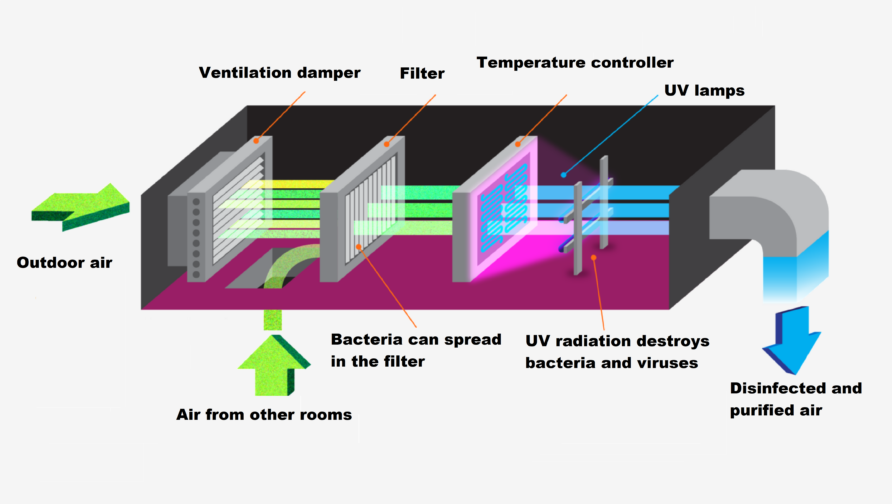

Over time, unwanted contaminants accumulate inside ventilation systems, which promotes the growth of harmful microorganisms. Conventional filters are not able to completely clean the air, so special UV sections are used to improve hygiene and air quality. These devices destroy bacteria and viruses by affecting their DNA with ultraviolet radiation, and therefore are widely used in enterprises and public places where high-quality air purification is required.

Basic operating principle

Ultraviolet air disinfection sections are placed directly in the ventilation ducts and perform targeted air treatment. As the air stream passes through the UV lamp zone, it is exposed to light wavelengths of about 254 Nm, a level at which UV light destroys the DNA of microbes, depriving them of the ability to reproduce. This makes UV irradiation an effective means of controlling microorganisms in air systems

The design of the germicidal air disinfection section includes several key components:

- Housing. Usually made of stainless steel or galvanized material that is UV and humidity resistant, extending the life of the unit.

- UV lamps. Low-pressure amalgam lamps are used, which provide high power and durability. Due to the use of mercury in the form of amalgam, they are safe and resistant to active airflow.

- Power control cabinet. This unit contains the electronic ballast, cooling system and lamp hour meter, allowing you to control the operation of the section.

- Connecting elements and wires. Designed with UV-resistant materials and designed for connection to ventilation ducts of different diameters.

- Lamp replacement window. Equipped with convenient fasteners for quick replacement for easy maintenance.

What is important to know during installation and maintenance

There are several factors to consider when installing the section to ensure its efficient and safe operation:

- Accessibility for maintenance: The UV section should be located so that it is easy to change lamps and carry out routine maintenance. In case of limited accessibility, it is recommended to provide a maintenance area.

- Convenient location of the control cabinet: A control cabinet equipped with an electronic ballast should preferably be installed within 10 meters of the section for ease of operation.

- Casing tightness: the UV section should be airtight to prevent UV radiation from entering the premises and endangering people.

- Temperature rating: the lamps are designed to operate within a temperature range of +10 to +35°C; failure to do so may reduce their effectiveness and life expectancy.

Selecting the right germicidal UV disinfection section

To choose the optimal model of UV section for ventilation, you need to take into account the following parameters:

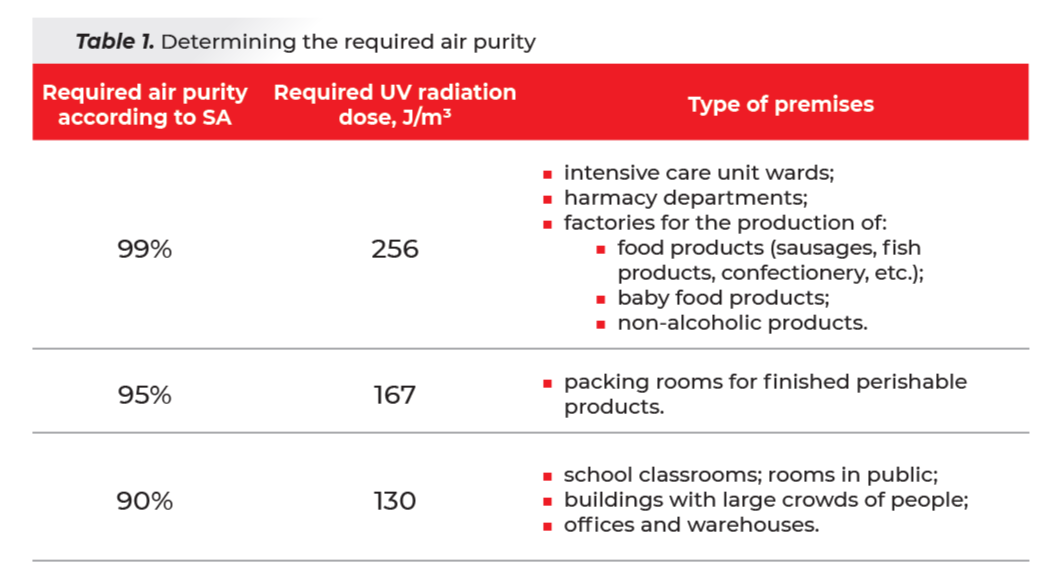

- The required air purity level. The level of air purity according to SA standards may vary depending on the purpose of the room. For example, in medical and public buildings require a higher degree of purification, from 90% and above.

- Ventilation duct size. The diameter and shape of the duct determines which section sizes will be most efficient.

- Volume of the room and ventilation capacity. For proper selection of UV lamp capacity, it is important to know how much air volume is treated by the system per hour (m³/h) and the area of the room.

Example of selecting a UV section for an office space

Let us consider an example: an office space with a ventilation capacity of 1680 m³/h. It is recommended to install the section after the recuperator to ensure that all the air is treated before it is delivered. The duct size, e.g. 300×400 mm, is also important for accurate equipment selection. According to office standards, the minimum air purity level is 90%, which corresponds to a UV dose of 130 J/m³.

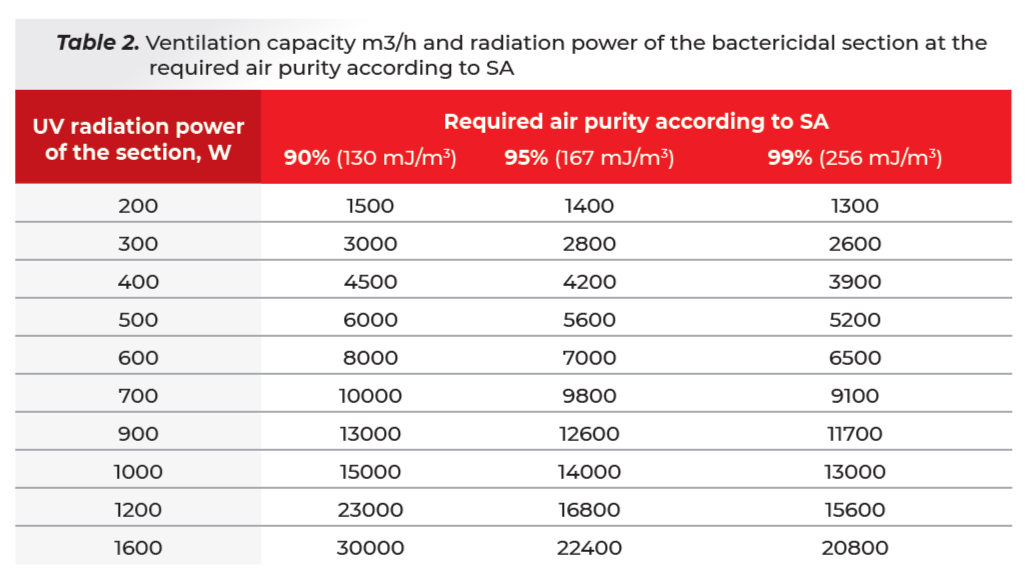

Using another table, we determine the required capacity of the section for disinfection of this type of room. For this purpose, in the column “Required air purity 90%” we find the value of our ventilation capacity. But, since 1680 m3/hour is absent in the table, we take the value rounded upwards - 3000 m3/hour. And we determine the required power of UV radiation of the section - 300 W.

This data allows you to choose a specific model of UVL-Aero germicidal section, suitable in terms of power and dimensions.

The use of UV sections for air disinfection is a modern way to protect against microorganisms in the air. Selecting and installing equipment from UVL will help to ensure clean air and reduce the risk of spreading disease in areas where a high level of sanitation is required.