Our company specializes in the development and manufacturing of ultraviolet (UV) equipment for water and air disinfection. With a well-stocked warehouse, equipped with all the necessary UV components, including lamps, quartz sleeves, electronic ballasts (EBRAs), and hermetic seals, we can promptly assemble orders of various scales and solve unique disinfection challenges.

The Project

We were approached by a client who manages ornamental fish ponds. The following ponds were involved:

- Pond No. 1: Volume of 1800 m³, filtration system capacity of 450 m³/hour, home to 20 sturgeon, with an average weight of 50 kg.

- Pond No. 2: Volume of 800 m³, filtration system capacity of 350 m³/hour, populated by carp.

Both ponds are integrated into a closed system with biofiltration and polypropylene storage tanks, where UV modules were required to be installed.

The Issue

The primary issue was the intensive “blooming” of the water caused by the rapid proliferation of bacteria, which negatively impacted the aesthetic appearance of the ponds and could pose a health risk to the inhabitants. Previous attempts using ozonators were ineffective due to the need for constant monitoring, low reliability, and unstable results. Given the presence of valuable fish species, it was essential to suppress algae growth efficiently without harming the ecosystem.

The Solution

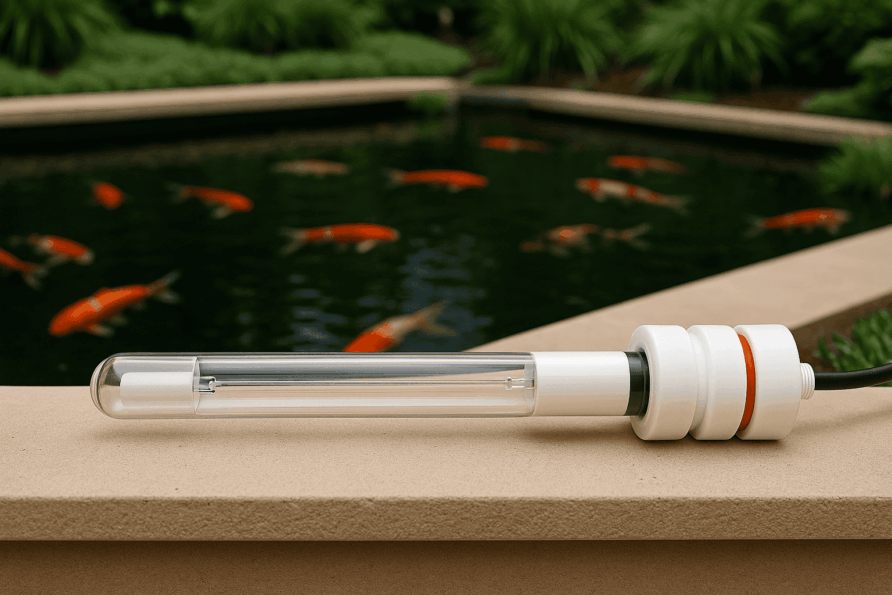

We proposed a solution based on in-duct UV disinfection. The water, after biofiltration, flows into polypropylene storage tanks, where submerged UV modules (UVL Mod 19180) are installed. After treatment, the water is returned to the pond. This setup ensures that the fish are not exposed to UV radiation directly, while still effectively inactivating algae and other microorganisms.

The choice of amalgam lamps was based on their high efficiency across a wide temperature range and their high UV radiation efficiency (COP), which is particularly important for seasonal use. These lamps generally offer a longer lifespan and more stable performance compared to traditional low-pressure lamps.

Specifications:

- Model: UVL Mod 19180

- Power: 172 W

- UV Radiation: 55 W (monochromatic, 254 nm)

- Lamp Type: Ozone-free amalgam

- Design: Quartz sleeve, fluoroplastic hermetic seal, silicone gaskets

- Power Supply: EBRL-220-1x200 with indicator

- Lifespan: 16,000 hours

- Required UV Dose: ≥ 40 mJ/cm²

- Delivery Volume: 24 modules for the first pond and 16 for the second

Implementation Process:

After an initial consultation with the engineer, calculations for the required UV radiation power were made based on the water volume, filtration speed, and the required disinfection level. A key task was to integrate the equipment into the existing tanks without altering the system configuration. Modules with threaded sealing connections were optimally suited for this task.

Thanks to the versatile design, the installation proceeded smoothly: the module is installed in the tank and secured with a nut, while the power supply is placed in a protected area. The equipment operates in continuous mode, ensuring the longevity of the lamps and maintaining a consistent disinfection effect. The continuous operation mode also helps prevent the regrowth of microorganisms.

Results and Benefits for the Client:

- The problem of water "blooming" was solved without the use of chemicals or ozone, complying with modern environmental safety standards.

- Maintenance convenience: The quartz sleeve can be mechanically and chemically cleaned to maintain optimal UV transmission efficiency.

- Fish safety was ensured as the disinfection process occurs outside the main pond.

- The equipment was delivered promptly, thanks to the necessary modules being available in stock.

If you're looking for an effective and safe solution to address water "blooming" in your pond, contact us. We’ll help you select the optimal UV equipment tailored to your specific needs.