Project Background

At this dairy plant, pasteurized milk is cooled to +5 °C and sent for packaging in bags. An inline UVL Aqua 40 system was already in place, but growing production volumes and stricter hygiene standards for packaging required additional measures. Space on the line was limited, making bulky equipment impractical, and maintaining product temperature was critical.

Challenges

The client’s requirements were to:

- Increase disinfection efficiency without altering the conveyor layout.

- Prevent even slight heating of the milk.

- Ensure two-sided ultraviolet disinfection of packaging film before sealing.

- Receive readily available equipment with short delivery times.

Solution – Upgrading UV Performance

Our engineers upgraded the Aqua 40 system by replacing its standard lamp with a more powerful UVL 15115 amalgam UV lamp (120 W). This improved UV intensity without changing the housing. The lamp operates effectively between +5 °C and +40 °C, ensuring no heating of the product. Each lamp was paired with an electronic ballast tailored to its parameters.

Two upgraded systems were shipped for pilot testing. Results confirmed a significant reduction in microbial load without affecting the milk’s physical or chemical properties.

Packaging Film Disinfection

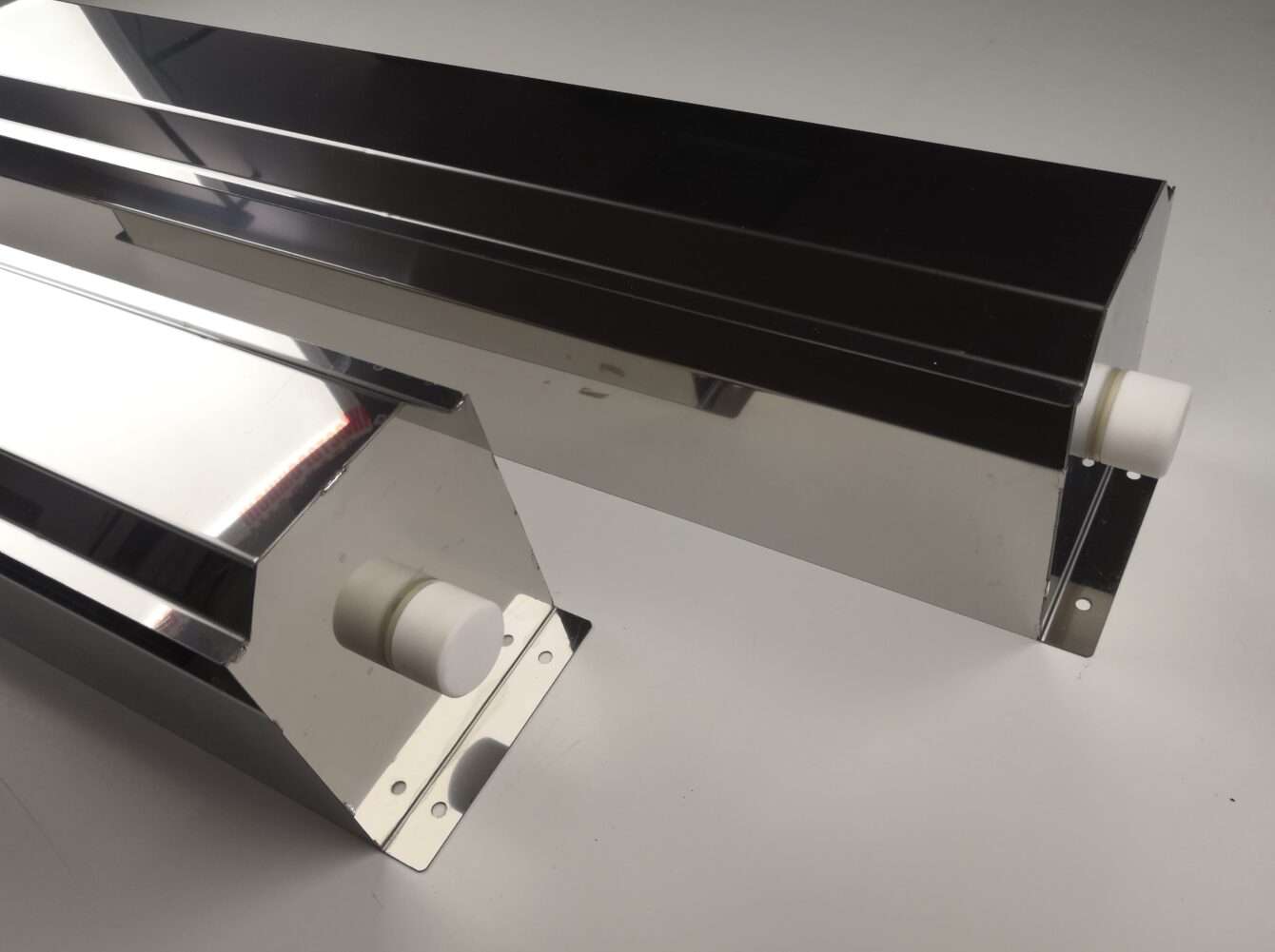

To sterilize the roll film, two VOZUF 810 mm UV units were installed—one above and one below the conveyor—to provide dual-sided exposure. A quartz plate supported the film while allowing UV light to pass through unobstructed.

Technical Highlights

- UVL 15115 Amalgam Lamp – 120 W power, 40 W UV output, 16,000-hour service life.

- Electronic Ballast L-220-1x120-2201-15 – 120 W peak power, 1.2 A current, 220/230 V, 50/60 Hz.

- VOZUF 810 mm UV Unit – 95 W lamp power, up to 25 W UV output, 253.7 nm spectrum, size 810×118×140 mm, effective zone up to 0.5 m.

Results Achieved

The upgrade was implemented without halting production. The milk’s temperature remained stable, and the packaging film underwent germicidal UV disinfection on both sides, improving hygiene. Testing showed a significant decrease in bacterial contamination. The client decided to scale the system up to 10 UV lamps for sequential product treatment. All deliveries were complete, on schedule, and included operating guidelines and inspection recommendations.