Project Snapshot

A contractor responsible for stormwater and sanitary networks needed to disinfect effluent after sand and oil separation, with a design flow of up to 600 L/s. The ultraviolet lamps had to be integrated into underground concrete tanks Ø 3,200 mm and > 7 m long. Installation was performed by the client’s crew, with close technical coordination throughout.

Challenges Identified

The initial design under-sized the UV stage—only two 100 L/s units per line—insufficient for real hydraulic conditions. Space constraints, flange orientation, cabinet cable runs, and service access also had to be resolved. The contractor requested phased shipping aligned with construction milestones.

Engineered Response

We rapidly re-worked the package and supplied two inline UV disinfection models:

- UVL-AQUA 15-700 – up to 440 m³/h, 15 amalgam germicidal lamps, 10,500 W total power.

- UVL-AQUA 17-700 – up to 550 m³/h, 17 lamps, 12,870 W total power.

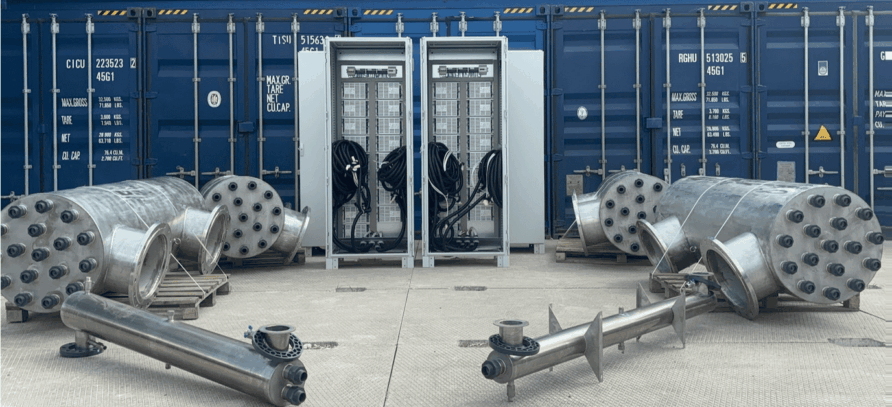

In total, 8 reactors were delivered (per line: two for 150 L/s and two for 100 L/s). For compact tie-in and maintenance, we used a U-shaped layout with single-axis nozzles, added lifting hooks, and provided 10 m cable sets to reach control cabinets. Housings were AISI 304 stainless steel (AISI 316 available on request).

Supply scope included:

- Outdoor-rated IP55 control cabinets with temperature, dust, and moisture protection.

- Automatic wash systems, operating-hour counters.

- Optional flow and UV intensity sensors for performance monitoring.

- Full drawings, wiring diagrams, equipment passports, and QC support at unloading.

Delivery plan: phased (2 + 2 units at 150 L/s, then 100 L/s systems) to sync with site works.

Outcome

The project was completed in 45 days, ahead of plan. Equipment was partially installed in the tanks and prepared for commissioning. The client noted fast redesign, flexible logistics, and hands-on support from concept through delivery.

Where This Fits Best

These UV sterilizers cover not only stormwater but also municipal utilities and industrial facilities in food & beverage, pharmaceuticals, and agri-processing. Typical capacities span 0.3–2,500 m³/h for potable water and up to 1,000 m³/h for wastewater.

If you need a turnkey UV disinfection system—from selection of quartz sleeves and electronic ballasts to project-matched flanges and cabinet layouts—we’ll configure, document, and ship a solution aligned with your flow and footprint.