Ultraviolet radiation is widely used across various industries, including aquaculture, where it plays a crucial role in Recirculating Aquaculture Systems (RAS). On fish farms, UV treatment helps maintain water purity, creating a healthy environment for fish growth and development. These systems effectively control pathogenic microorganisms, reducing the risk of diseases and contributing to environmental safety.

How does UV water treatment work?

UV systems operate by passing water through a sterilization chamber equipped with UV lamps emitting light at a wavelength of 254 nm. This radiation destroys the DNA and RNA of microorganisms, such as bacteria and viruses, preventing their reproduction. At the same time, the chemical composition of the water remains unchanged, and its essential properties, such as taste and odor, are preserved.

Should UV sterilizers be installed before or after filtration?

For maximum efficiency, UV equipment is installed after filtration for several reasons:

- Removal of mechanical impurities – Filters (sand, diatomaceous) remove large and small particles, reducing water turbidity. Without pre-filtration, UV radiation cannot effectively penetrate contaminated water.

- Extended service life – Installing UV sterilizers after filters reduces the load on UV lamps and other components, decreasing equipment wear.

- Quartz sleeve maintenance – The transparency of the quartz sleeve directly affects sterilization efficiency. Regular cleaning helps maintain a high bactericidal effect.

How to choose a UV sterilizer for RAS?

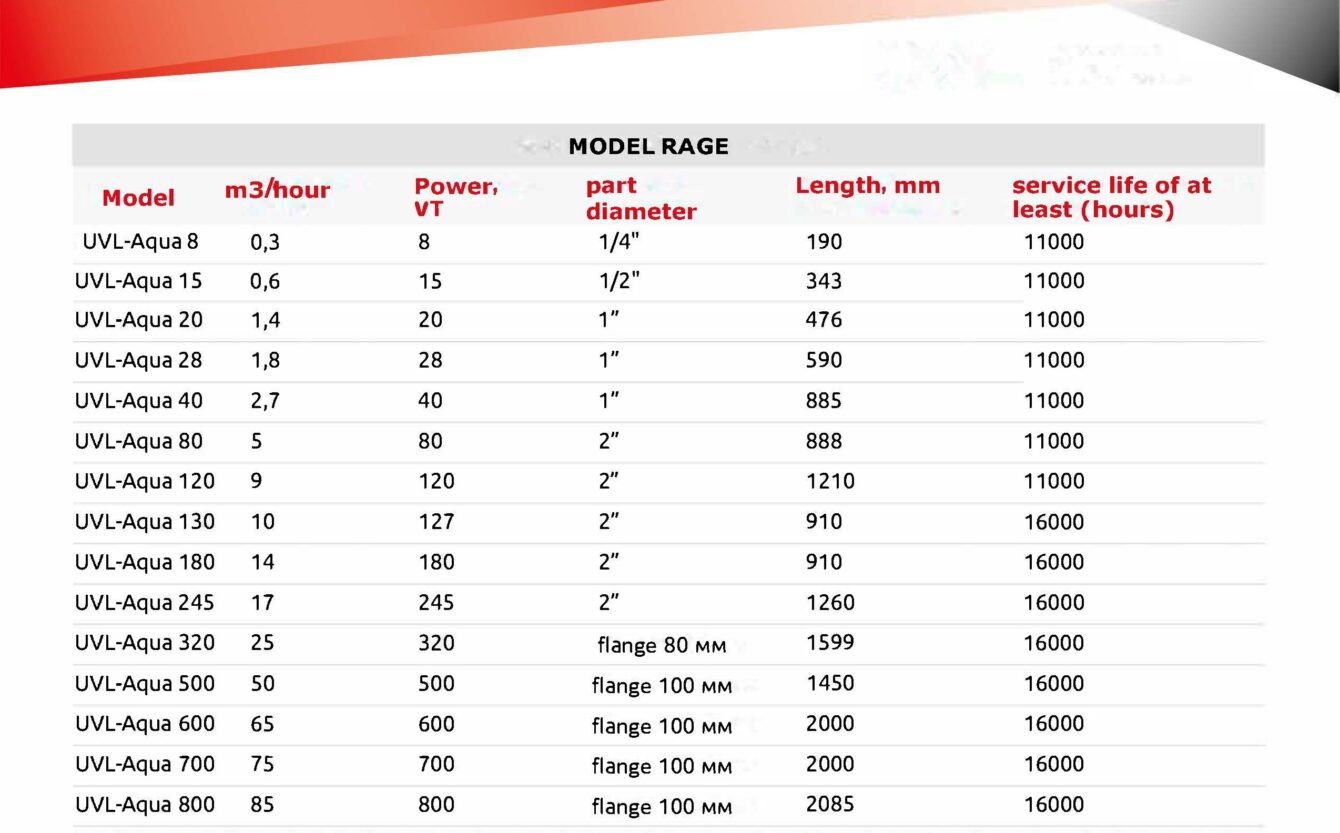

Flow-through UV systems are commonly used in fish farms, such as the UVL-Aqua series, which handle large water volumes. When selecting equipment, it is important to consider pump power and the volume of treated water. Knowing these parameters allows for the accurate calculation of the required UV dose, ensuring optimal sterilization efficiency. For precise equipment selection, consulting with technical specialists is recommended.

Advantages of UV treatment in fish farming

Using UV disinfection in aquaculture is an eco-friendly and effective method for water treatment. It helps:

- Reduce disease risks and improve fish survival rates

- Lower costs associated with chemical water treatment

- Minimize environmental impact

- Create optimal conditions for fish growth and development

Combining UV with other treatment methods

Ozonation is also widely used on fish farms. Ozone is a powerful oxidizing agent that quickly eliminates organic contaminants, improving water clarity and removing odors. However, high ozone concentrations can be hazardous for both fish and personnel.

In such cases, UV radiation not only disinfects the water but also breaks down residual ozone, making the treatment process safer. Many fish farms combine ozone generators with UV sterilizers to achieve maximum efficiency.

Conclusion

The use of UV equipment in aquaculture is a safe and modern method that helps maintain fish health and reduces the risk of diseases. Proper selection and operation of UV systems allow for the creation of ideal conditions for successful fish farming and breeding.

UVL offers a wide range of UV equipment and components, and our specialists are ready to assist in selecting solutions tailored to your needs. For more details, visit our website.