At the end of 2024, a utility engineering company approached us with a request to implement a UV disinfection system for wastewater at a newly commissioned facility. The challenge: ensure reliable performance inside a confined underground fiberglass chamber while achieving high throughput.

The client specified a vertical, U-shaped design capable of processing at least 75 liters per second. The system also had to include a weatherproof control cabinet and an automatic cleaning module. The goal was to maintain a UV dose of 40 mJ/cm², meeting the strict microbial reduction criteria for water discharged into sensitive ecosystems.

Unrealistic Promises from Competitors

The customer had a competing offer promising a 275 m³/h output with 7.5 kW power and a 40 mJ/cm² dose. However, our technical team reviewed the details and found inconsistencies: delivering that dose at the specified pipe diameter (DN 300) was highly doubtful. A realistic expectation would be closer to 30 mJ/cm².

Our Offer: Reliable and Efficient UV System

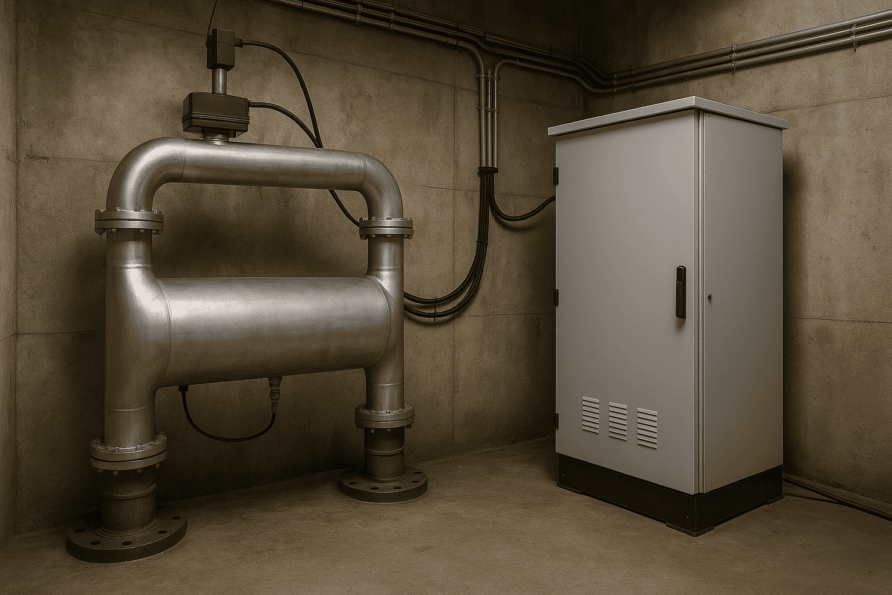

We proposed the UVL-Aqua 12-700, a powerful and adaptable UV disinfection lamp system designed to match real-world demands. The unit includes twelve amalgam lamps known for their extended lifespan and energy efficiency. The vertical U-shaped stainless steel chamber (AISI 304) was ideal for the confined underground setting.

Additional components included a street-grade control cabinet with integrated heating, a UV sterilizer cleaning system, and fully documented installation instructions.

Key Specifications – UVL-Aqua 12-700:

- Max Flow Rate: up to 800 m³/h (at 25 mJ/cm²)

- Flow Rate at 30 mJ/cm²: 340 m³/h

- UV Dose: 30 mJ/cm²

- Lamps: 12 x UVL-32700 amalgam lamps, 16,000-hour lifespan

- Material: AISI 304 stainless steel

- Configuration: Vertical, U-shaped

- Control Cabinet: 12-channel with active cooling, IP65 protection, automatic ventilation

- Accessories: Cleaning unit, installation guide, electrical diagrams, foundation recommendations

Overcoming Tight Deadlines and Constraints

Despite tight deadlines, personnel shortages, and late-arriving components, the project remained on schedule. We ensured constant communication with the client and provided all project documentation in full, including design drawings, wiring diagrams, and technical passports.

Final Setup Included:

- UVL-Aqua 12-700 wastewater UV sterilizer

- Outdoor-rated electronic control cabinet with cooling

- Automatic cleaning module

- Full technical documentation set

- Site-specific installation recommendations

The equipment was fully completed and prepared for shipment by late February. The client appreciated our flexibility, transparency, and the quality of technical support from initial consultation to final approval.

Looking for a UV disinfection system tailored to your unique environment?

Whether you're dealing with wastewater or potable water, UVL builds custom solutions designed to perform